Call us at 714.247.1288

"We'll Keep You Cold!"

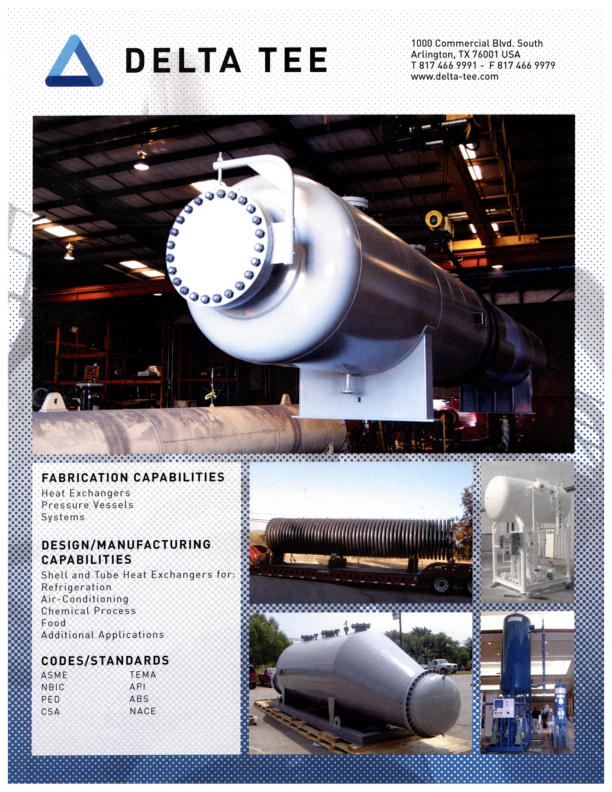

DELTA TEE INTERNATIONAL, INC.

Delta Tee International, Inc was founded in 2003 by a group of engineers who bring over 30 years of solid experience in the design and fabrication of shell and tube heat exchangers and pressure vessels. Currently our company has grown to employ over 70 professionals and is recognized as one of the industry’s most reliable suppliers of heat transfer equipment.

DESIGN

The Delta Tee Application and Design Engineering team has the in-depth thermal and mechanical knowledge required to develop, produce and support our products. For optimal accuracy and efficiency we utilize the latest available releases of specialized software like Aspen Thermal, Aspen Mechanical, DesignCalcs, Solidworks and AutoCAD. Even though it is our standard to supply equipment designed and fabricated to the requirements of ASME Section VIII, Division 1 Code and TEMA (in the case of shell and tube heat exchangers), over the years we have gained extensive experience in complying with other international standards such as PED, AS, MIGAS and DOSH. Since a significant percentage of our products are used on the territory of Canada, design registrations (CRN) with any or all provinces have become common practice.

MANUFACTURING

Delta Tee employs skilled fabricators who can be relied upon to complete the task at hand no matter the degree of difficulty and challenge it presents. Our manufacturing process has been optimized to achieve a high rate of on-time deliveries without compromising product cost and quality. To support the wide variety of applications for our shell and tube heat exchangers, we have successfully developed many welding procedures for joining not only carbon and stainless steel grades, but also exotic metals such as titanium and duplex steels. The in-house machining center has been customized for our product line with expanded dimensional capabilities in CNC turning, milling and drilling operations.

QUALITY CONTROL

The Quality Control program is in strict accordance with a formal Quality Control System based on the requirements of all applicable ASME Code sections. Our main facility and associated proximity locations are authorized by ASME and NBBPVI to manufacture, certify and register products with the U marking, as well as to perform pressure equipment repairs and alterations under the R symbol. The inspection methodology and procedures are clearly detailed in a written Manual, an uncontrolled copy of which is available upon request.

QUALITY ASSURANCE

The Quality Assurance concepts at Delta Tee have been developed by using the fundamentals of ISO9000 philosophy, while maintaining the flexibility and expediency of a more informal system. We strive to provide the ultimate in customer service and support, therefore our claim is that a complicated system of internal approvals can only be detrimental to the response time required by our Customers. Multiple client surveys of our operation have been unanimous in their findings that the implemented system assures that Delta Tee can consistently meet and exceed expectations. Through all phases of order fulfillment, from contract review to final assessment and documentation, activities are monitored directly by top management and, when required, corrective/preventive action is immediate.